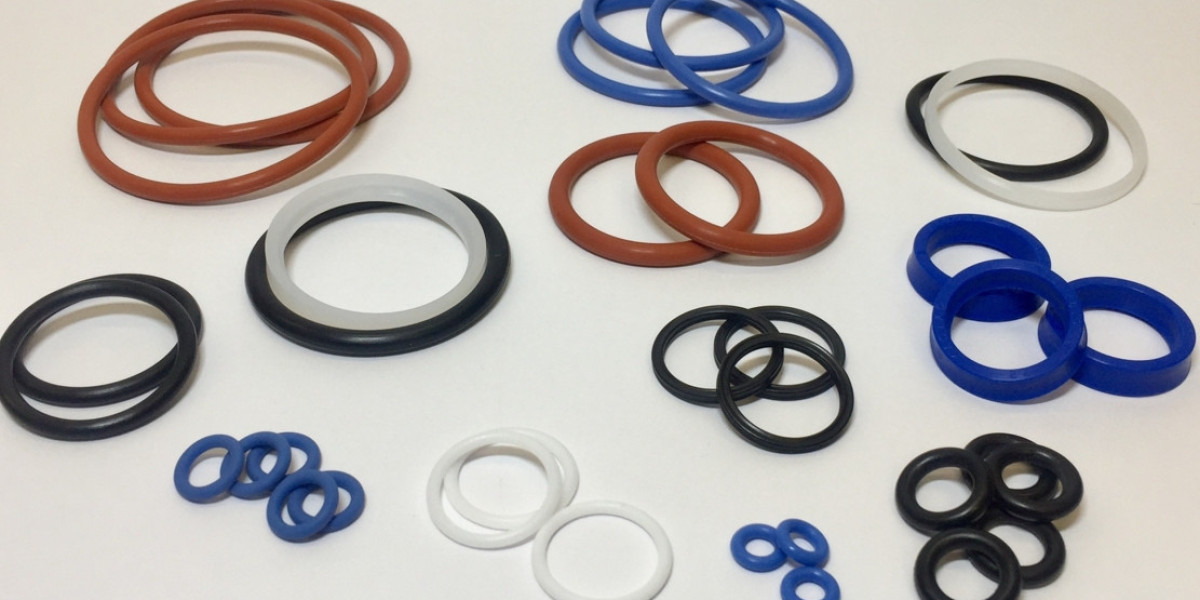

When it comes to sealing solutions in various industries, O-rings are among the most commonly used components due to their simple design and effective sealing capabilities. One type of O-ring that stands out for its reliability and versatility is the seamless spliced O-ring. These specialized O-rings are designed for high-performance applications where standard O-rings may not suffice. In this article, we’ll dive deep into the advantages of seamless spliced O-rings, their uses, and how they are manufactured.

What are Seamless Spliced O-Rings?

A seamless spliced O-ring is a custom-made sealing solution created by joining the ends of an elastomeric material in a continuous loop, without any joint overlap or external seam. The process typically involves precision splicing techniques to ensure a smooth and continuous seal. Unlike traditional O-rings, which are molded or cut into a standard ring shape, seamless spliced O-rings are made from a continuous strip of elastomer that is spliced and fused together, creating a seamless finish.

The seamless nature of these O-rings makes them ideal for applications where the integrity of the seal is paramount, and there’s a need for minimal defects or weak points.

Manufacturing Process of Seamless Spliced O-Rings

The manufacturing process of seamless spliced O-rings involves the following key steps:

Material Selection: A variety of elastomer materials can be used for seamless spliced O-rings, including rubber compounds like nitrile, silicone, EPDM, and Viton. The choice of material depends on the operating environment, temperature range, and chemical compatibility required by the application.

Splicing: The material is carefully cut into a continuous strip, then the ends are joined using a specialized splicing process. This is done with precision equipment that bonds the two ends using heat, pressure, or adhesive to create a continuous loop without a visible joint or seam. The splicing process is critical in ensuring that the O-ring maintains its integrity and does not develop leaks.

Finishing: After the splicing process, the O-ring is inspected for any imperfections. It is then cut to the required dimensions and subjected to quality control tests to ensure it meets the necessary standards.

Advantages of Seamless Spliced O-Rings

Enhanced Durability: The absence of seams or joints in a seamless spliced O-ring reduces the risk of leakage, wear, or failure. This is especially important in high-pressure or high-temperature environments where traditional O-rings might be prone to defects at the joint.

Improved Seal Integrity: The continuous, seamless structure of these O-rings ensures a more consistent and reliable seal, preventing leaks even in critical applications.

Customizable Sizes: Seamless spliced O-rings can be made to any size or specification required, offering versatility in applications across industries. This is especially useful when dealing with non-standard or customized sealing requirements.

Cost-Effective: While seamless spliced O-rings may initially appear more expensive due to the precision involved in their manufacturing, they can actually be more cost-effective over time due to their longer lifespan and reduced maintenance needs.

Resistance to Harsh Environments: Depending on the material used, seamless spliced O-rings can offer exceptional resistance to extreme temperatures, chemicals, oils, and gases. This makes them ideal for industries such as automotive, aerospace, chemical processing, and oil & gas.

Applications of Seamless Spliced O-Rings

Seamless spliced O-rings are used across a variety of industries that demand high-performance seals. Some key applications include:

Aerospace: In aircraft, spacecraft, and satellite applications, where high pressure, vibration, and extreme temperatures are common, seamless spliced O-rings offer a reliable sealing solution.

Automotive: Seamless spliced O-rings are often used in automotive engines, pumps, and hydraulic systems for fluid containment and pressure control.

Oil & Gas: In the oil and gas industry, where exposure to chemicals, oils, and gases is a constant concern, these O-rings help to prevent leaks in machinery and pipelines.

Pharmaceuticals & Food Processing: In industries where hygiene is critical, seamless spliced O-rings help maintain contamination-free seals in pumps, valves, and processing equipment.

Chemical Processing: The chemical industry uses these O-rings for their resistance to aggressive chemicals and extreme temperatures, ensuring that tanks, reactors, and other equipment remain sealed without risk of leaks.

Conclusion

Seamless spliced O-rings are an essential sealing solution for many high-performance applications that require durability, precision, and reliability. By eliminating weak points like seams and joints, these O-rings provide superior sealing capabilities, making them an ideal choice for industries with demanding requirements. Whether in aerospace, automotive, or chemical processing, seamless spliced O-rings deliver the strength and longevity needed to keep systems running smoothly.

When selecting O-rings for your application, it’s important to consult with an experienced supplier who can help determine the right material and specifications for your needs. Seamless spliced O-rings, with their exceptional sealing performance and customizable features, are an excellent choice for critical sealing tasks in a wide range of industries.