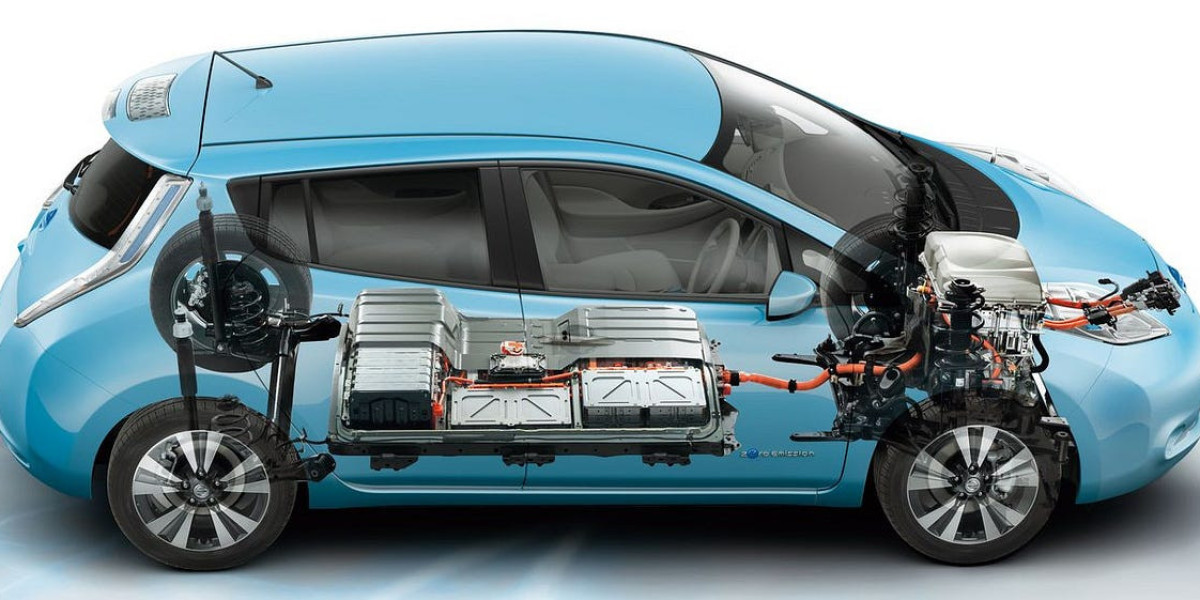

The United Kingdom Electric Vehicle Battery Recycling Market is poised for significant growth as the demand for electric vehicles (EVs) continues to rise. As more consumers and businesses transition to electric mobility, the need for sustainable and efficient methods of recycling EV batteries has become increasingly urgent. Electric vehicle batteries, particularly lithium-ion batteries, are essential components that power EVs but also pose environmental challenges at the end of their life cycle. The United Kingdom Electric Vehicle Battery Recycling Market is playing a crucial role in addressing these challenges, enabling the safe recovery of valuable materials, reducing environmental impact, and supporting the circular economy.

Overview of the Electric Vehicle Battery Recycling Market in the UK

The electric vehicle battery recycling market is focused on recovering valuable materials such as lithium, cobalt, nickel, and graphite from used EV batteries. These materials are critical for the production of new batteries, making recycling an essential part of the EV supply chain. As the adoption of electric vehicles accelerates in the UK, so does the volume of end-of-life batteries that need to be properly disposed of or repurposed. Recycling these batteries not only reduces the need for mining new raw materials but also helps mitigate the environmental risks associated with improper disposal.

The UK government’s commitment to achieving net-zero carbon emissions by 2050, coupled with regulations mandating the responsible disposal of EV batteries, has created a supportive framework for the growth of the electric vehicle battery recycling market. The UK is already taking steps to ensure that the infrastructure for battery recycling is ready to handle the increasing volume of waste batteries, with both domestic recycling initiatives and international partnerships.

Key Drivers of the Market

1. Increasing EV Adoption

The most significant driver of the electric vehicle battery recycling market in the UK is the rapid increase in the adoption of electric vehicles. As the UK pushes toward achieving its goal of a cleaner, greener transportation sector, EVs are becoming more common on the roads. According to recent statistics, the number of electric vehicles in the UK has seen a sharp rise, and this trend is expected to continue. This increase directly correlates with the demand for battery recycling services, as each EV will eventually require battery disposal or recycling.

2. Government Regulations and Sustainability Goals

The UK government has implemented several measures to ensure the responsible recycling of EV batteries. This includes the Batteries and Accumulators Regulations, which require producers to take responsibility for the collection and recycling of waste batteries. Additionally, the government’s broader sustainability goals, such as reducing carbon emissions and increasing the circular economy, are also encouraging investment in recycling technologies and infrastructure. The combination of these regulations and policies has spurred both private and public sectors to invest in EV battery recycling facilities and processes.

3. Environmental Impact of Battery Disposal

As the global concern over climate change intensifies, there is growing pressure to ensure that the materials used in EV batteries are recycled rather than disposed of in landfills. Improper disposal of batteries can result in the release of harmful chemicals into the environment, including heavy metals and toxic substances. Recycling these batteries helps prevent such environmental damage, reduces the need for mining, and conserves valuable raw materials.

Market Segmentation

The United Kingdom Electric Vehicle Battery Recycling Market can be segmented based on technology, battery type, and end-use industry.

1. By Technology

Mechanical Recycling: This method involves physically breaking down batteries to recover valuable materials like lithium, cobalt, and nickel. It’s a simpler process but can sometimes be less efficient compared to more advanced methods.

Hydrometallurgical Recycling: In this process, chemicals are used to extract metals from the battery components. It is considered to be more efficient than mechanical recycling, especially for recovering rare metals.

Pyrometallurgical Recycling: This involves using high temperatures to melt down batteries and recover metals. While effective for some materials, this process can be more energy-intensive and less environmentally friendly.

2. By Battery Type

Lithium-Ion Batteries: These are the most common type of battery used in electric vehicles and account for the majority of the market share. Lithium-ion batteries are highly efficient and have a relatively long lifespan, but they require careful recycling due to the presence of hazardous materials.

Nickel-Metal Hydride (NiMH) Batteries: While less common in newer EV models, NiMH batteries are still used in older electric vehicle models. They have a different recycling process compared to lithium-ion batteries but can still be efficiently recycled for their nickel and rare earth materials.

Solid-State Batteries: As the technology advances, solid-state batteries are being developed as an alternative to lithium-ion batteries. These batteries are still in the early stages of adoption, but they hold the potential to change the landscape of the electric vehicle battery recycling market in the future.

3. By End-Use Industry

Automotive Manufacturers: A significant portion of the market is driven by the need for recycling by EV manufacturers. Car manufacturers and battery producers are keen on sourcing recycled materials to reduce production costs and dependence on raw materials.

Recycling Facilities: Specialized facilities focused on the processing and recycling of spent batteries play a key role in the supply chain. These facilities extract valuable metals, refine them, and return them to the manufacturing process.

Research and Development: R&D activities focused on improving battery recycling technologies are also a growing segment of the market. Innovations in recycling efficiency and the development of new methods for recovering more materials from batteries are crucial to supporting the long-term sustainability of the electric vehicle industry.

Technological Innovations and Trends

1. Advanced Recycling Methods

Recent advancements in battery recycling technologies are improving the efficiency and sustainability of the process. Companies are investing in new technologies, such as direct recycling methods and more effective hydrometallurgical processes, which aim to reduce energy consumption and environmental impact. Additionally, the development of “closed-loop” recycling systems, where materials from used batteries are returned to the production cycle, is gaining traction.

2. Automated and AI-Driven Sorting

Artificial intelligence (AI) and robotics are making their way into the recycling process, offering improvements in sorting and dismantling used EV batteries. Automation can reduce labor costs, increase processing speed, and improve the precision of material recovery. AI algorithms can also help predict battery life cycles and optimize the recycling process.

3. Battery Second Life Programs

Another emerging trend is the concept of giving EV batteries a "second life" before recycling them. This involves repurposing used EV batteries for energy storage applications, such as in grid systems or for residential use. By extending the lifespan of these batteries, companies can reduce the number of batteries needing recycling and provide an additional source of revenue.

Key Market Players

Several companies in the UK are investing heavily in the electric vehicle battery recycling market. These players include large multinational corporations such as Johnson Matthey, Veolia, and Lithium Recycling Ltd., as well as newer, innovative startups focusing on battery technology and recycling. These companies are working on improving the efficiency of recycling methods, expanding recycling capacity, and forging partnerships with EV manufacturers to ensure a steady supply of end-of-life batteries for recycling.

Challenges and Barriers

While the UK electric vehicle battery recycling market has significant growth potential, several challenges remain. One of the primary issues is the complexity of recycling lithium-ion batteries, which require specialized processes due to the variety of materials they contain. Additionally, there is a lack of widespread infrastructure for recycling facilities, particularly outside major urban areas. The high cost of establishing and maintaining recycling facilities, combined with fluctuating demand for recycled materials, can also pose challenges.

Future Outlook

The future of the United Kingdom Electric Vehicle Battery Recycling Market looks highly promising as the EV industry continues to expand. As battery technology evolves, so too will recycling methods, with a focus on greater efficiency and environmental sustainability. The development of new, advanced recycling technologies and the continued push for policies supporting a circular economy will be key to the long-term success of the market.

In conclusion, the United Kingdom Electric Vehicle Battery Recycling Market is set for sustained growth, driven by increased EV adoption, government regulations, and technological advancements in recycling methods. With the right investments in infrastructure and technology, the UK can lead the way in creating a sustainable, closed-loop system for battery recycling, reducing environmental impact and supporting the green economy.

More Trending Reports