Cost To Build Water Tower By Type

Cost To Build Water Tower By Type If you lay a small basis of 81 sq. toes, you’ll need one cubic yard of concrete per four inches of foundation thickness. You can also have the ability to have a single pump from well to tank, particularly if you’re not using it for drinking water. At current market rates, that’s roughly $1.38 million in metal prices alone, as a lot of the tower was prefabricated. Here, concrete prices a mean of about $125-$180 per cubic yard. On the other hand, ultra-high-performance concrete costs $300-$390 per cubic yard. Often, you can also pay close to 2.5% of the entire project charge as well. In any case where you put collectively a non-pre-fabricated water tower, you’ll have to contain an architect.

What Is the Average Cost of Forced Draft Cooling Towers?

Fuel Tanks

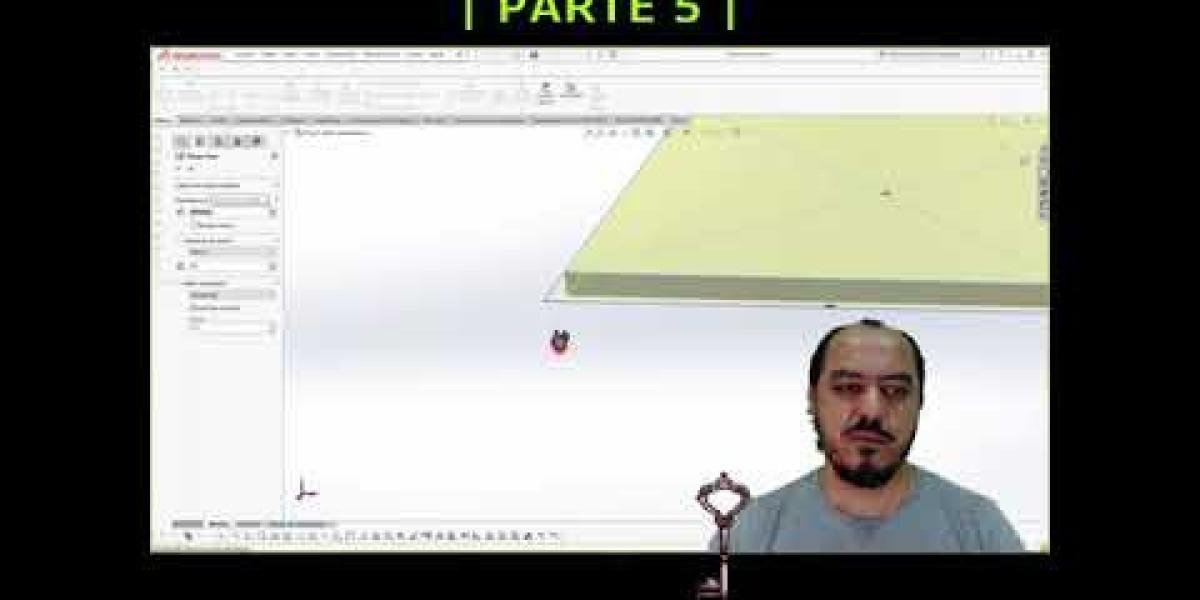

To keep the fluid clear filter parts are normally installed within the reservoir or externally to wash the returning fluid. Reservoirs which may be filled by pouring fluid immediately into them have a strainer within the filler well to strain out impurities when fluid is added. The amount of fluid in the reservoir is indicated by a direct reading sight gauge, a clear tube, or a float/dial gauge. All of the fabricating and machining work along with the finishing and testing are completed by our expert group. Our customer, an agile and prestigious business jet producer, was growing a new aircraft for a premium market segment.

These custom metal reservoirs have been used in a variety of applications by our customers nationwide, caixa d água castelo including:

As a frontrunner in custom metal fabrication, we now have the data, the expertise, and the equipment to fabricate tankes to the specs required on your project. Our manufacturing capabilities run the gamut from heavy gauge, strong tanks designed for use in harsh environmental conditions to mild gauge tanks requiring tight tolerances and significant floor finishes. From hydraulic tanks for earthmoving tools to gas tanks for motorcycles and every thing in between, leading OEMs from all industries turn to ATACO Steel Products for his or her tank fabrication needs. Complete testing, paint, and assembly line preparation of fabricated reservoirs is accomplished in our in-house facilities.

Tanks and Reservoirs

A course of consisting of leak testing, washing, rinsing, and an oil flush ensure the reservoirs are free of defects and Www.iway.lk ready for installation in Fork Lift vans. As a rule of thumb the ideal reservoir will maintain about 2 ½ occasions the pump output per minute. The benefits of a big reservoir are generally sacrificed because of space limitations in mobile methods. As a minimal they should be giant enough to accommodate thermal expansion of the fluid and modifications in fluid degree because of system operation. Request a quote on custom strain vessel fabrication, or contact us for more information. Discover why so many major corporations have made ATACO their first selection as a stress vessel manufacturer.

CB&I is the world's main designer and builder of storage services, tanks and terminals. An elevated water tank is vulnerable to freezing in under zero temperatures, which in flip may leave the community and not using a reliable water supply. A number of water tank heating strategies may be implemented to stop freezing, including gravity circulation, steam coils, and/or direct steam discharge. Biothane was chosen for construction of a wastewater facility in support of a distillery in St. Croix.

Based on the meant utility and needs of the distribution area, elevated water tanks may be engineered using a broad range of shapes, sizes, and materials. Caldwell’s welded metal floor storage tanks are low price, versatile in a seismic event or basis settlement, and can simply be modified or retrofitted. Our ground storage tanks are designed with the best quality carbon or stainless-steel to ensure sturdiness and longevity. Designed to fulfill the needs of varied industries, our floor storage tanks provide a protected and efficient approach to retailer giant portions of water or chemicals.

Based on the meant utility and needs of the distribution area, elevated water tanks may be engineered using a broad range of shapes, sizes, and materials. Caldwell’s welded metal floor storage tanks are low price, versatile in a seismic event or basis settlement, and can simply be modified or retrofitted. Our ground storage tanks are designed with the best quality carbon or stainless-steel to ensure sturdiness and longevity. Designed to fulfill the needs of varied industries, our floor storage tanks provide a protected and efficient approach to retailer giant portions of water or chemicals.We are extraordinarily expert within the manufacture of gasoline and hydraulic tanks that are primarily used in the material handling and off-road car industries. Most reservoirs have a capped opening for filling, an air vent, an oil level indicator or dip stick, a return line connection, a pump inlet or suction line connection, a drain line connection, and a drain plug. A properly designed reservoir has inner baffles to forestall excessive sloshing of the fluid and to place a partition between the fluid return line and the pump suction line. The partition forces the returning fluid to journey farther around the tank earlier than being drawn again through the pump inlet line. This does 3 things; it helps cool the fluid extra successfully, aids in settling contaminants to the bottom and separates air from the fluid. A hydraulic system has a reserve of fluid along with that contained within the different components of the system.